- Combined clearing

- Enhanced detection modes

Total Contamination Control (TCC) - for managing remaining contaminants in yarns at minimum possible cost

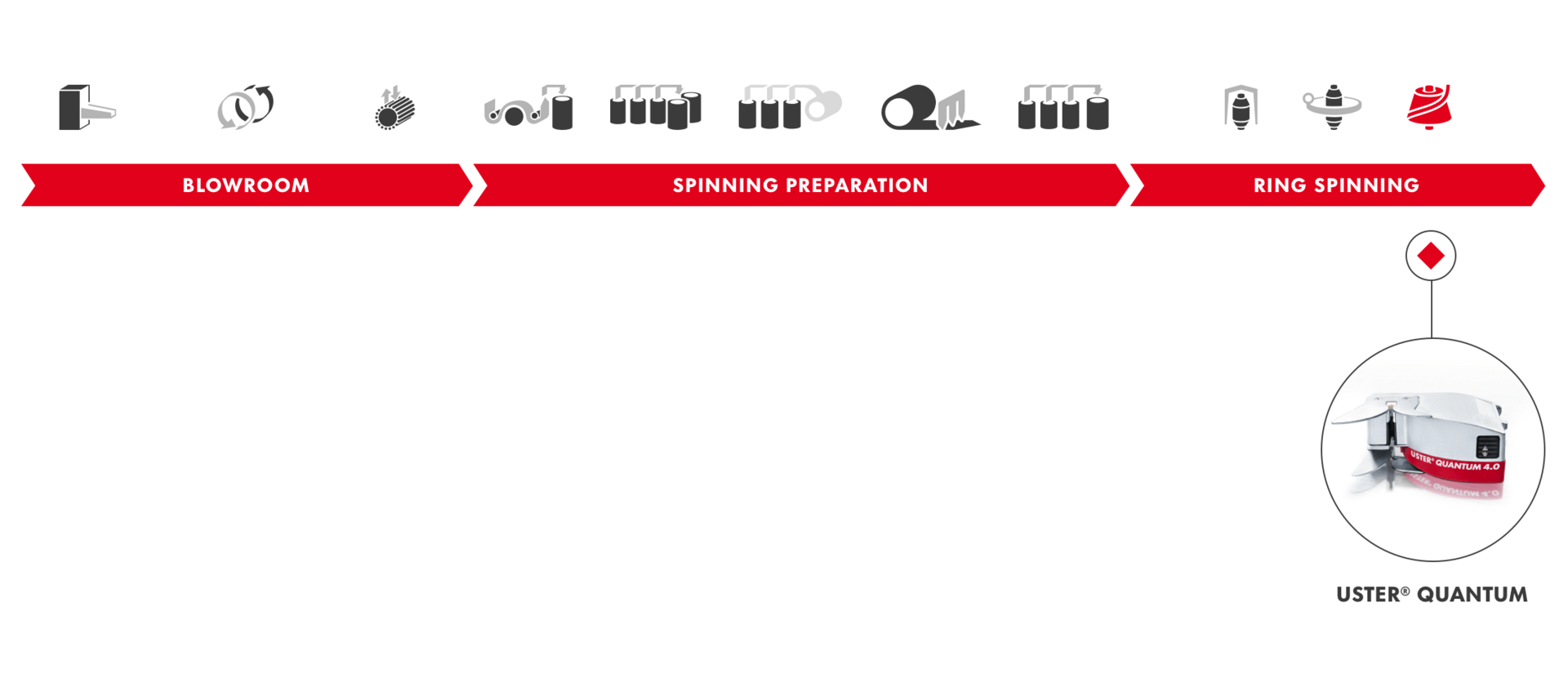

Uster Quantum 4.0 ensures yarn quality in winding with the smart combination of capacitive and optical signals. Connection to further Uster systems prevents issues at source.

Applicable to different yarns and changing conditions

Uster Quantum 4.0 combines capacitive and optical yarn clearing. This all-in-one solution offers full flexibility for various yarns and changing conditions.

An easy-to-use and reliable system: the user-interface is simple and quick to learn, and the well-established Quantum technology ensures a long service life with dependable hardware and software.

100% in-line monitoring includes Uster Quantum Expert and offers further optimization potential through connection to the platform Uster Quality Expert or Uster RSO 3D. This allows spinners to stay in control throughout the spinning process and to prevent issues at source.

The combination of both capacitive and optical signals opens up opportunities for new detection channels. The strength of both signals is an asset for the value of yarn quality and smooth operations in downstream processes. Smart Duo Technology addresses daily issues of spinning mills effectively to prevent costly claims.

The user-friendly Smart Clearing Technology eases the burden on spinning mills when defining yarn clearer settings. Production efficiency is increased by cutting only what needs to be cut.

Contamination is still the main problem of spinning mills. Powerful sensor with multicolored light sources enables unique visualization of dense areas and smart limits. Separate classification and clearing of dark and light foreign fibers, vegetable matter and polypropylene.

Increased diversity in the textile market with more and more innovative materials driven by fashion, sports and sustainability. Mix-ups of different raw materials and their blends occur easily as they are hardly visible to the human eye. Uster Quantum 4.0 takes care of this with a smart combination of signals. Continuous measurement of blend mix-up for raw white yarns.

Included with Uster Quantum 4.0, the newly designed Uster Quantum Expert is fully featured and compatible with previous Quantum generations. Prevention continues as a guiding principle in yarn clearing and according to the value modules of Uster Quality Expert. Automated data handling makes the most of the yarn clearer information ensuring yarn quality and productivity.

Total Contamination Control (TCC) - for managing remaining contaminants in yarns at minimum possible cost

Mill analysis - insightful analytics for data-based decisions

Alarm center - creates awareness and triggers action

Preventive yarn clearing stands for secured yarn quality in a flexible and efficient manner, cutting only what is necessary. With preventive yarn clearing, defects can even be eliminated at source, avoiding poor quality being produced.

Uster Quantum 4.0 - The connected yarn quality assurance system

Uster Textile Technology is our competence center for textile know-how and innovation. Meet our textile experts – and benefit from our expertise in textile manufacturing.

Uster tailor-made services ensure operational reliability and extend product life cycles at a favorable price. Over 200 qualified service professionals provide support worldwide, on-premise or remotely.

In case you can’t find your country, please refer to our offices here

EURL ALINK Import Export

Uster products (excl. Fabric Inspection)

Cite 300 Logts Elzahir C14 Local 001

M'sila

Unionmatex SARL

Uster products (excl. Fiber Cleaning)

18 Rue Abdelouahab Az-Zaqqaq

Belvedere

20310 Casablanca

Jose Fuster, S.L.

Francesc Layret, 12-14 Nave 29

08630 Abrera

Electro Core Repair Services

Uster products (excl. Fabric Inspection)

7 Abelia Road

Asherville

4091 Durban

Texmaco Pty Ltd

19 Verona Crescent

7210 Stanford

Pampa Kraft S.A.

Av. Fondo de la Legua 235

B1609JEC Boulogne

Pcia. Buenos Aires

AST Tech Australasia Pty. Ltd.

13 Chris Court

3037 Hillside, Victoria

AST Tech Australasia Pty. Ltd.

Uster products (excl. Fabric Inspection)

13 Chris Court

3037 Hillside, Victoria

Otto Kühnen GmbH & Co KG

Uster products (excl. Fiber Cleaning and Fabric Inspection)

Liechtensteinstrasse 63

1090 Wien

Elmatex GmbH Electronic und Maschinen für die Industrie

Uster Fabric Inspection products only

Uerdinger Strasse 149

47799 Krefeld

JV Textile Service Solutions LLC

Uster products (excl. Fabric Inspection)

Qumariq Street 49

100044 Tashkent

Martex Global Limited

Unit 1210-1214

41 Heung Yip Road

Wong Chuk Hang

Rauf Electronic Equipment Service

3-C-2/18, Nazimabad

74600 Karachi

Texcorp Trading Ltd.

117/A Tejgaon I/A

Dhaka 1208

Texcorp Trading Ltd.

117/A Tejgaon I/A

Dhaka 1208

Eletex Group BV

Uster Fabric Inspection products only

Houtstraat 8

9800 Deinze

Honoré SAS

Uster products (excl. Fabric Inspection)

10, rue Louis Néel

Synergie Park

59260 Lezennes

Societé de Services pour l’Europe et pour l’Afrique (SOSEA)

Uster products (excl. Fabric Inspection)

Route des Alizés, Zone Industrielle Est

76430 Sandouville

SARL COT.I.M.E.S.

Uster products (excl. Fabric Inspection)

10, Parc du Millénaire

1025 Avenue Henri Bequerel

34000 Montpellier

Intercom Ltda.

Calle Hans Kundt 757

Zona Miraflores

La Paz

Elettrotex Apparecchiature Elettroniche S.r.l.

Via Leonardo da Vinci 129

20090 Trezzano s/Naviglio (MI)

Electro Core Repair Services

Uster products (excl. Fabric Inspection)

7 Abelia Road

Asherville

4091 Durban

Texmaco Pty Ltd

19 Verona Crescent

7210 Stanford

Cotextil Representaçao Comercial Ltda

Uster products (excl. Fabric Inspection)

Rua Voluntarios da Patria, 1444

Centro

85812-160 Cascavel-PR

Elettrotex Apparecchiature Elettroniche S.r.l.

Via Leonardo da Vinci 129

20090 Trezzano s/Naviglio (MI)

Societé de Services pour l’Europe et pour l’Afrique (SOSEA)

Uster products (excl. Fabric Inspection)

Route des Alizés, Zone Industrielle Est

76430 Sandouville

SARL COT.I.M.E.S.

Uster products (excl. Fabric Inspection)

10, Parc du Millénaire

1025 Avenue Henri Bequerel

34000 Montpellier

Electro Core Repair Services

Uster products (excl. Fabric Inspection)

7 Abelia Road

Asherville

4091 Durban

Societé de Services pour l’Europe et pour l’Afrique (SOSEA)

Uster products (excl. Fabric Inspection)

Route des Alizés, Zone Industrielle Est

76430 Sandouville

SARL COT.I.M.E.S.

Uster products (excl. Fabric Inspection)

10, Parc du Millénaire

1025 Avenue Henri Bequerel

34000 Montpellier

C.A. Kennedy Inc.

9900 Ray Lawson, Ville d'Anjou

H1J1L8 Quebec

Societé de Services pour l’Europe et pour l’Afrique (SOSEA)

Uster products (excl. Fabric Inspection)

Route des Alizés, Zone Industrielle Est

76430 Sandouville

Societé de Services pour l’Europe et pour l’Afrique (SOSEA)

Uster products (excl. Fabric Inspection)

Route des Alizés, Zone Industrielle Est

76430 Sandouville

Catec

242, Abdelsalam Aref Street

Apt. 103, Loran

21411 Alexandria

SARL COT.I.M.E.S.

Uster products (excl. Fabric Inspection)

10, Parc du Millénaire

1025 Avenue Henri Bequerel

34000 Montpellier

Comercial Pacific Ltda.

Cordillera 331

Flexcenter D-13

Quilicura-Santiago

Uster Technologies (China) Co., Ltd.

Building B, 538 Fengting Avenue,

Suzhou Industrial Park, 215122

Suzhou, Jiangsu Province,

P.R. China

Retexa S.A.S.

Calle 9a Sur 11 111 - Int 128

050022 Medellin

Societé de Services pour l’Europe et pour l’Afrique (SOSEA)

Uster products (excl. Fabric Inspection)

Route des Alizés, Zone Industrielle Est

76430 Sandouville

Electro Core Repair Services

Uster products (excl. Fabric Inspection)

7 Abelia Road

Asherville

4091 Durban

SARL COT.I.M.E.S.

Uster products (excl. Fabric Inspection)

10, Parc du Millénaire

1025 Avenue Henri Bequerel

34000 Montpellier

Maprimaq, S.A.

Calzada Roosevelt 22-43 zona 11,

Tikal Futura

Torre Sol, Oficina 9D

Guatemala Ciudad

Elettrotex Apparecchiature Elettroniche S.r.l.

Via Leonardo da Vinci 129

20090 Trezzano s/Naviglio (MI)

Josef Kopecky

Uster products (excl. Fabric Inspection)

Druzstevni 1406

562 06 Usti nad Orlici

High End Vision Rafal Mierzwa

Uster Fabric Inspection products only

C3 18C

32-086 Wegrzce

Otto Kühnen GmbH & Co KG

Uster products (excl. Fiber Cleaning and Fabric Inspection)

Liechtensteinstrasse 63

1090 Wien

Alberto Rigoli Pacca

Uster products (excl. Fabric Inspection)

Urb. Santa Rosa L6

Norberto Salazar N7 - 19

Tumbaco

170184 Quito

Otto Seidlitz Representaciones Cia. Ltda.

German Aleman E10-44 y Av. 6 di Diciembre

170504 Quito

Catec

242, Abdelsalam Aref Street

Apt. 103, Loran

21411 Alexandria

Catec

Uster products (excl. Fabric Inspection)

242, Abdelsalam Aref Street

Apt. 103, Loran

21411 Alexandria

Nobeltex SARL

Uster Fabric Inspection products only

161 Rue du Kiem

8030 Strassen

Luxembourg

Maprimaq, S.A.

Uster Fiber Cleaning products only

Calzada Roosevelt 22-43 zona 11,

Tikal Futura

Torre Sol, Oficina 9D

Guatemala Ciudad

Texma Limitada

Uster products (excl. Fiber Cleaning)

Av. El Boqueron # 4-B

Santa Elena

Antiguo Cuscatlan

La Libertad

LLC "Service Center Textiltechnika"

Uster products (excl. Fabric Inspection)

Klyazminskaya Street 11-2-30

127644 Moscow

Electro Core Repair Services

Uster products (excl. Fabric Inspection)

7 Abelia Road

Asherville

4091 Durban

Texmaco Pty Ltd

19 Verona Crescent

7210 Stanford

Catec

242, Abdelsalam Aref Street

Apt. 103, Loran

21411 Alexandria

Novac AG

Uster products (excl. Fiber Cleaning and Fabric Inspection)

lm Langacker 5

4144 Arlesheim

Honoré SAS

10, rue Louis Néel

Synergie Park

59260 Lezennes

Electro Core Repair Services

Uster products (excl. Fabric Inspection)

7 Abelia Road

Asherville

4091 Durban

Societé de Services pour l’Europe et pour l’Afrique (SOSEA)

Uster products (excl. Fabric Inspection)

Route des Alizés, Zone Industrielle Est

76430 Sandouville

Elmatex GmbH Electronic und Maschinen für die Industrie

Uster Fabric Inspection products only

Uerdinger Strasse 149

47799 Krefeld

Ingenieurbüro Gerd Schwarz GmbH

USTER® products (excl. Fabric Inspection)

Pestalozzistr. 91

72762 Reutlingen

Societé de Services pour l’Europe et pour l’Afrique (SOSEA)

Uster products (excl. Fabric Inspection)

Route des Alizés, Zone Industrielle Est

76430 Sandouville

Novac AG

Uster products (excl. Fiber Cleaning and Fabric Inspection)

lm Langacker 5

4144 Arlesheim

West Riding Agencies Limited

125 Sapgate Lane

Thornton, Bradford

West Yorkshire BD13 3DY

Georgios Tzivelopoulos & Cie E.E. e-TEXELCO

Athanasiou Diakou 15

Marousi 15122, Athens

Maprimaq, S.A.

Calzada Roosevelt 22-43 zona 11,

Tikal Futura

Torre Sol, Oficina 9D

Guatemala Ciudad

Societé de Services pour l’Europe et pour l’Afrique (SOSEA)

Uster products (excl. Fabric Inspection)

Route des Alizés, Zone Industrielle Est

76430 Sandouville

SARL COT.I.M.E.S.

Uster products (excl. Fabric Inspection)

10, Parc du Millénaire

1025 Avenue Henri Bequerel

34000 Montpellier

Societé de Services pour l’Europe et pour l’Afrique (SOSEA)

Uster products (excl. Fabric Inspection)

Route des Alizés, Zone Industrielle Est

76430 Sandouville

Maprimaq, S.A.

Calzada Roosevelt 22-43 zona 11,

Tikal Futura

Torre Sol, Oficina 9D

Guatemala Ciudad

High End Vision Rafal Mierzwa

Uster Fabric Inspection products only

C3 18C

32-086 Wegrzce

Otto Kühnen GmbH & Co KG

Uster products (excl. Fiber Cleaning and Fabric Inspection)

Liechtensteinstrasse 63

1090 Wien

Uster Technologies (India) Pvt. Ltd.

1st Floor, Sam Surya Towers

1168, Avinashi Road,

P. N. Palayam

Coimbatore 641037

India

PT. Gansa Techno Center

Kopo Plaza Blok G-5

Jl. Peta Lingkar Selatan

Kelurahan Sukaasih

Kecamatan Bojongloa Kaler

Bandung

Jawa Barat 40233

PT. Gansa Techno Center

Kopo Plaza Blok G-5

Jl. Peta Lingkar Selatan

Kelurahan Sukaasih

Kecamatan Bojongloa Kaler

Bandung

Jawa Barat 40233

West Riding Agencies Limited

125 Sapgate Lane

Thornton, Bradford

West Yorkshire BD13 3DY

Weinstein & Namir (1994) Ltd.

Uster products (excl. Fabric Inspection)

47 Vatikim Street

4051447 Even-Yehuda

Uster Technologies Ltd.

Industrial Park Caesarea North

Bareket 7, POB 3047

Caesarea

Israel

Elettrotex Apparecchiature Elettroniche S.r.l.

Via Leonardo da Vinci 129

20090 Trezzano s/Naviglio (MI)

Sacconaghi Monaco SRL

Uster Fabric Inspection products only

Via San Gregorio 12

20124 Milano

Societé de Services pour l’Europe et pour l’Afrique (SOSEA)

Uster products (excl. Fabric Inspection)

Route des Alizés, Zone Industrielle Est

76430 Sandouville

SARL COT.I.M.E.S.

Uster products (excl. Fabric Inspection)

10, Parc du Millénaire

1025 Avenue Henri Bequerel

34000 Montpellier

Uster Technologies K.K.

3rd Floor Edge Esaka,

Toyotsu-cho 9-1, Suita

Osaka 564-0051

Japan

JV Textile Service Solutions LLC

Uster products (excl. Fabric Inspection)

Qumariq Street 49

100044 Tashkent

Martex Global Limited

Unit 1210-1214

41 Heung Yip Road

Wong Chuk Hang

Electro Core Repair Services

Uster products (excl. Fabric Inspection)

7 Abelia Road

Asherville

4091 Durban

Novac AG

Uster products (excl. Fiber Cleaning and Fabric Inspection)

lm Langacker 5

4144 Arlesheim

Martex Global Limited

Unit 1210-1214

41 Heung Yip Road

Wong Chuk Hang

LLC "Service Center Textiltechnika"

Uster products (excl. Fabric Inspection)

Klyazminskaya Street 11-2-30

127644 Moscow

Electro Core Repair Services

Uster products (excl. Fabric Inspection)

7 Abelia Road

Asherville

4091 Durban

Texmaco Pty Ltd

19 Verona Crescent

7210 Stanford

Societé de Services pour l’Europe et pour l’Afrique (SOSEA)

Uster products (excl. Fabric Inspection)

Route des Alizés, Zone Industrielle Est

76430 Sandouville

Catec

242, Abdelsalam Aref Street

Apt. 103, Loran

21411 Alexandria

LLC "Service Center Textiltechnika"

Uster products (excl. Fabric Inspection)

Klyazminskaya Street 11-2-30

127644 Moscow

Eletex Group BV

Uster Fabric Inspection products only

Houtstraat 8

9800 Deinze

Honoré SAS

USTER® products (excl. Fabric Inspection)

10, rue Louis Néel

Synergie Park

59260 Lezennes

Electro Core Repair Services

Uster products (excl. Fabric Inspection)

7 Abelia Road

Asherville

4091 Durban

Texmaco Pty Ltd

19 Verona Crescent

7210 Stanford

Electro Core Repair Services

Uster products (excl. Fabric Inspection)

7 Abelia Road

Asherville

4091 Durban

Texmaco Pty Ltd

19 Verona Crescent

7210 Stanford

LH TechTex Sdn. Bhd.

35 Lengkok Berjaya

10350 Penang

Prutech Marketing Snd Bhd

No. 95, Jalan KIP 9

Taman Perindustrian KIP

Kepong

52200 Kuala Lumpur

Societé de Services pour l’Europe et pour l’Afrique (SOSEA)

Uster products (excl. Fabric Inspection)

Route des Alizés, Zone Industrielle Est

76430 Sandouville

SARL COT.I.M.E.S.

Uster products (excl. Fabric Inspection)

10, Parc du Millénaire

1025 Avenue Henri Bequerel

34000 Montpellier

Societé de Services pour l’Europe et pour l’Afrique (SOSEA)

Uster products (excl. Fabric Inspection)

Route des Alizés, Zone Industrielle Est

76430 Sandouville

SARL COT.I.M.E.S.

Uster products (excl. Fabric Inspection)

10, Parc du Millénaire

1025 Avenue Henri Bequerel

34000 Montpellier

Electro Core Repair Services

Uster products (excl. Fabric Inspection)

7 Abelia Road

Asherville

4091 Durban

Texmaco Pty Ltd

19 Verona Crescent

7210 Stanford

Blutec S.A. de C.V.

Calzada Zavaleta 3920 Local 2

Santa Cruz Buenavista

72170 Puebla, Pue.

Blutec S.A. de C.V.

Calzada Zavaleta 3920 Local 2

Santa Cruz Buenavista

72170 Puebla, Pue.

Unionmatex SARL

Uster products (excl. Fiber Cleaning)

18 Rue Abdelouahab Az-Zaqqaq

Belvedere

20310 Casablanca

Electro Core Repair Services

Uster products (excl. Fabric Inspection)

7 Abelia Road

Asherville

4091 Durban

Texmaco Pty Ltd

19 Verona Crescent

7210 Stanford

Electro Core Repair Services

Uster products (excl. Fabric Inspection)

7 Abelia Road

Asherville

4091 Durban

Texmaco Pty Ltd

19 Verona Crescent

7210 Stanford

Ingenieursbureau Wendrich & Co B.V.

Deldenerstraat 126

7551 AK Hengelo Ov.

AST Tech Australasia Pty. Ltd.

13 Chris Court

3037 Hillside, Victoria

AST Tech Australasia Pty. Ltd.

Uster products (excl. Fabric Inspection)

13 Chris Court

3037 Hillside, Victoria

Maprimaq, S.A.

Calzada Roosevelt 22-43 zona 11,

Tikal Futura

Torre Sol, Oficina 9D

Guatemala Ciudad

Societé de Services pour l’Europe et pour l’Afrique (SOSEA)

Uster products (excl. Fabric Inspection)

Route des Alizés, Zone Industrielle Est

76430 Sandouville

SARL COT.I.M.E.S.

Uster products (excl. Fabric Inspection)

10, Parc du Millénaire

1025 Avenue Henri Bequerel

34000 Montpellier

Electro Core Repair Services

Uster products (excl. Fabric Inspection)

7 Abelia Road

Asherville

4091 Durban

Novac AG

Uster products (excl. Fiber Cleaning and Fabric Inspection)

lm Langacker 5

4144 Arlesheim

Rauf Electronic Equipment Service

3-C-2/18, Nazimabad

74600 Karachi

Simag Enterprises FZCO

HD-193, Floor 23

Sheikh Rashid Tower

Dubai World Trade Center

United Arab Emirates

Pampa Kraft S.A.

Av. Fondo de la Legua 235

B1609JEC Boulogne

Pcia. Buenos Aires

Rheintek Peru S.A.C.

Calle Boulevard 141-145, Ofic. 1001

Urb. Hogares de Monterrico Chico

Santiago de Surco

Lima

Agnessi Trading

1665 Interior 16

Angel Linao Street

Paco

1007 Manila

High End Vision Rafal Mierzwa

Uster Fabric Inspection products only

C3 18C

32-086 Wegrzce

3PM Pawel Prym

Uster Fabric Inspection products only

A. Struga 7/7

90-420 Lodz

Otto Kühnen GmbH & Co KG

Uster products (excl. Fiber Cleaning and Fabric Inspection)

Liechtensteinstrasse 63

1090 Wien

J. Baptista & C.a.L.da

Rua Dos Vanzeleres, 337

4100-484 Porto

J. Baptista & C.a.L.da

Rua Dos Vanzeleres, 337

4100-484 Porto

Catec

Uster products (excl. Fabric Inspection)

242, Abdelsalam Aref Street

Apt. 103, Loran

21411 Alexandria

Societé de Services pour l’Europe et pour l’Afrique (SOSEA)

Uster products (excl. Fabric Inspection)

Route des Alizés, Zone Industrielle Est

76430 Sandouville

Amytex & Partners SRL

Aleea Teisani Nr 296, Camera nr.5

Corp 39, Bloc A67, Etaj 4, Ap.44

Sector 1

014034 Bucuresti

Romania

Electro Core Repair Services

Uster products (excl. Fabric Inspection)

7 Abelia Road

Asherville

4091 Durban

Societé de Services pour l’Europe et pour l’Afrique (SOSEA)

Uster products (excl. Fabric Inspection)

Route des Alizés, Zone Industrielle Est

76430 Sandouville

Elettrotex Apparecchiature Elettroniche S.r.l.

Via Leonardo da Vinci 129

20090 Trezzano s/Naviglio (MI)

Societé de Services pour l’Europe et pour l’Afrique (SOSEA)

Uster products (excl. Fabric Inspection)

Route des Alizés, Zone Industrielle Est

76430 Sandouville

Societé de Services pour l’Europe et pour l’Afrique (SOSEA)

Uster products (excl. Fabric Inspection)

Route des Alizés, Zone Industrielle Est

76430 Sandouville

SARL COT.I.M.E.S.

Uster products (excl. Fabric Inspection)

10, Parc du Millénaire

1025 Avenue Henri Bequerel

34000 Montpellier

Societé de Services pour l’Europe et pour l’Afrique (SOSEA)

Uster products (excl. Fabric Inspection)

Route des Alizés, Zone Industrielle Est

76430 Sandouville

Societé de Services pour l’Europe et pour l’Afrique (SOSEA)

Uster products (excl. Fabric Inspection)

Route des Alizés, Zone Industrielle Est

76430 Sandouville

SARL COT.I.M.E.S.

Uster products (excl. Fabric Inspection)

10, Parc du Millénaire

1025 Avenue Henri Bequerel

34000 Montpellier

Prutech Marketing Snd Bhd

No. 95, Jalan KIP 9

Taman Perindustrian KIP

Kepong

52200 Kuala Lumpur

Josef Kopecky

Uster products (excl. Fabric Inspection)

Druzstevni 1406

562 06 Usti nad Orlici

Otto Kühnen GmbH & Co KG

Uster products (excl. Fiber Cleaning and Fabric Inspection)

Liechtensteinstrasse 63

1090 Wien

Elettrotex Apparecchiature Elettroniche S.r.l.

Via Leonardo da Vinci 129

20090 Trezzano s/Naviglio (MI)

Electro Core Repair Services

Uster products (excl. Fabric Inspection)

7 Abelia Road

Asherville

4091 Durban

Texmaco Pty Ltd

19 Verona Crescent

7210 Stanford

Corvet Tech Asia Co., Ltd.

Uster products (excl. Fiber Cleaning)

Room #802, Botanic Park Tower 2

GongHangDae-Ro 213, GangSeo-Gu

07802 Seoul

Corvet Tech Asia Co., Ltd.

Uster products (excl. Fiber Cleaning)

Room #802, Botanic Park Tower 2

GongHangDae-Ro 213, GangSeo-Gu

07802 Seoul

Paik Inc.

Uster Fiber Cleaning products only

(Yeouido-dong, Donghwa Bldg.), 1008

71, Yeouinaru-ro, Yeongdeungpo-gu

Seoul

Catec

242, Abdelsalam Aref Street

Apt. 103, Loran

21411 Alexandria

Jose Fuster, S.L.

Francesc Layret, 12-14 Nave 29

08630 Abrera

Jose Fuster, S.L.

Francesc Layret, 12-14 Nave 29

08630 Abrera

SPJ Holdings (Pvt) Ltd

Uster Fabric Inspection products only

359 Park Road

Colombo 05

Catec

242, Abdelsalam Aref Street

Apt. 103, Loran

21411 Alexandria

Uster Technologies AG (HQ)

Sonnenbergstrasse 10

8610 Uster

Switzerland

Multicom Machinery Taiwan Ltd.

Uster products (excl. Fiber Cleaning)

11 Floor, No. 99 Chung Shan North Road, Sec.2

10445 Taipei

Multicom Machinery Taiwan Ltd.

Uster products (excl. Fiber Cleaning)

11 Floor, No. 99 Chung Shan North Road, Sec.2

10445 Taipei

Timtex Trading Co.,Ltd.

Uster Fiber Cleaning products only

9F-8, No.413 Lin-Sen North Road

Zhongshan District

Taipei

JV Textile Service Solutions LLC

Uster products (excl. Fabric Inspection)

Qumariq Street 49

100044 Tashkent

Martex Global Limited

Unit 1210-1214

41 Heung Yip Road

Wong Chuk Hang

Electro Core Repair Services

Uster products (excl. Fabric Inspection)

7 Abelia Road

Asherville

4091 Durban

Novac AG

Uster products (excl. Fiber Cleaning and Fabric Inspection)

lm Langacker 5

4144 Arlesheim

Ulster Service Co.,Ltd

171 Soi Pattanakarn 65 Yaek 5

Khwaeng Prawet, Khet Prawet

10250 Bangkok

Avitex Co., Ltd.

Uster Fiber Cleaning products only

No. 16, Soi Krung Thep Kritha 8 Yeak 2 (Pridi)

Hua Mak Sub-District

Bang Kapi District

Bangkok 10240

Ulster Service Co.,Ltd

171 Soi Pattanakarn 65 Yaek 5

Khwaeng Prawet, Khet Prawet

10250 Bangkok

Societé de Services pour l’Europe et pour l’Afrique (SOSEA)

Uster products (excl. Fabric Inspection)

Route des Alizés, Zone Industrielle Est

76430 Sandouville

SARL COT.I.M.E.S.

Uster products (excl. Fabric Inspection)

10, Parc du Millénaire

1025 Avenue Henri Bequerel

34000 Montpellier

Catec

242, Abdelsalam Aref Street

Apt. 103, Loran

21411 Alexandria

Sebatex

16, Rue de l’Inde

1002 Tunis

Uster Teknoloji Ticaret A.Ş

Belediye Evleri Mah. 84220 Sok.

İnci Park Sitesi No:2

Çukurova/Adana

Türkiye

NV. A & A Demeulenaere

Uster products (excl. Fiber Cleaning)

Kruisstraat 1

8840 Westrozebeke

Electro Core Repair Services

Uster products (excl. Fabric Inspection)

7 Abelia Road

Asherville

4091 Durban

Novac AG

Uster products (excl. Fiber Cleaning and Fabric Inspection)

lm Langacker 5

4144 Arlesheim

LLC "Service Center Textiltechnika"

Uster products (excl. Fabric Inspection)

Klyazminskaya Street 11-2-30

127644 Moscow

Rauf Electronic Equipment Service

3-C-2/18, Nazimabad

74600 Karachi

Simag Enterprises FZCO

HD-193, Floor 23

Sheikh Rashid Tower

Dubai World Trade Center

United Arab Emirates

Uster Technologies, Inc.

319 Garlington Road,

Suite B4

Greenville, SC 29615

USA

Pampa Kraft S.A.

Av. Fondo de la Legua 235

B1609JEC Boulogne

Pcia. Buenos Aires

JV Textile Service Solutions LLC

Uster products (excl. Fabric Inspection)

Qumariq Street 49

100044 Tashkent

Martex Global Limited

Unit 1210-1214

41 Heung Yip Road

Wong Chuk Hang

Elettrotex Apparecchiature Elettroniche S.r.l.

Via Leonardo da Vinci 129

20090 Trezzano s/Naviglio (MI)

Representaciones Surmatra, S.A.

Apartado Postal 88056

Prado del Este

1080A Caracas

Gia Huy Trading and Technologies Company Limited

7/8/5 Ly Te Xuyen Street, Hamlet 4

Linh Dong Ward, Thu Duc City

Ho Chi Minh City

My Hao International Trading Co. Ltd.

Uster products (excl. Fiber Cleaning)

79/13 Pham Thai Buong Street

Phu My Hung, Tan Phong Ward, District 7

Ho Chi Minh City

Timtex Trading Co.,Ltd.

Uster Fiber Cleaning products only

9F-8, No.413 Lin-Sen North Road

Zhongshan District

Taipei

Societé de Services pour l’Europe et pour l’Afrique (SOSEA)

Uster products (excl. Fabric Inspection)

Route des Alizés, Zone Industrielle Est

76430 Sandouville

Electro Core Repair Services

Uster products (excl. Fabric Inspection)

7 Abelia Road

Asherville

4091 Durban

Texmaco Pty Ltd

19 Verona Crescent

7210 Stanford

Electro Core Repair Services

Uster products (excl. Fabric Inspection)

7 Abelia Road

Asherville

4091 Durban

Texmaco Pty Ltd

19 Verona Crescent

7210 Stanford

Uster RSO 3D increases profitability with direct process optimization and traceability from ring spinning to winding.

Learn more

The Quality Management Platform for advanced process optimization in yarn manufacturing, assuring quality from fiber to yarn.

Learn more

The Uster Jossi Vision Shield contamination sorter is a trustworthy partner for every spinner: it detects everything but only removes what is necessary.

Learn more